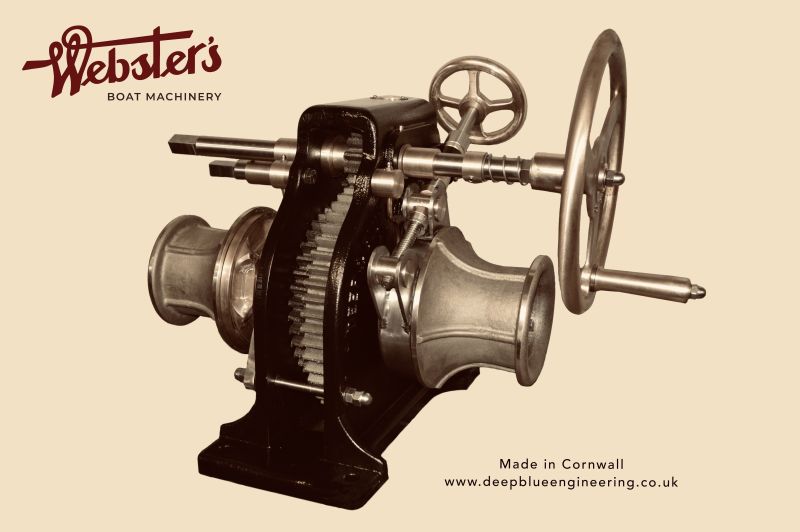

The No.2 Dual Ratio windlass is suitable for use with vessels of up to 45 tonnes displacement. It can be supplied with a gypsy to operate with chain from 12 mm to 14 mm. It can be configured with a wide range of specifications, both with the materials used in its construction and the over all functionality. The dual ratios offer 4.3:1 low ratio or 2.5:1 high ratio.

The basic specification windlass would be fitted with a chain gypsy, a hand wheel operated brake and a warping drum. However, functionality can be added, to a point where the windlass has two chain gypsies, each with hand wheel operated brakes, two warping drums and two clutches so that both warping drums and gypsies can be operated independently. For example, a warping drum could be used to raise a top mast or sail, whilst the vessel is at anchor.

The basic specification level in terms of materials used in the windlass construction (what we call 'work boat' specification) is painted iron housing, gypsy and warping drum. However, it is possible for the entire windlass to be made from bronze if desired.

For more information, click on Additional Information, related products or downloads, at the bottom of the page.

- No.2 DR Windlass Additional Information

-

No.2 Dual Ratio windlass is supplied as standard with one crank handle although a hand wheel can also be specified by the customer if desired. A spare crank handle can be ordered as an accessory, which can be useful, allowing two operators to work together and share the load. In circumstances where there is heavy lifting to be done, for example when an anchor is set deep in a muddy anchorage following a strong blow, a ratchet handle can be a useful accessory, by effectively doubling the length of the lever, when compared to the standard crank handle. To obtain detailed specifications, dimensional information, operating procedures and associated technical data sheets, please click on downloads below.

- Safety

-

With deck machinery generally there is a need to take great care and maintain a high level of awareness with regard to the moving parts of both the machinery and associated equipment such as ground tackle, chain, ropes etc. Operating and Maintenance details can be downloaded from this site, and should be read and understood before attempting to operate the windlass. The procedures for anchor deployment and retrieval provide warnings, aimed at alerting the operator to potential hazards and therefore it is essential that the procedures are followed carefully.

- Maintenance

-

There are three main aspects to the maintenance of these windlasses. The first is a periodic, basic visual check, to establish there are no loose fastenings or any other anomalies which require attention. The frequency of this inspection will depend on how often the windlass is used, and will be at the discretion of the owner/skipper. Sail training and charter businesses use these windlasses, and it is common for the anchor to be used, sometimes several times in one day. Under these circumstances is is beneficial to make checks frequently, perhaps weekly, through the season. On most privately owned leisure vessels however, the inspection frequency could be monthly through the season, but clearly it is good practice to keep a vigilant eye on systems and machinery at all times. The second aspect is lubrication. The main shaft bearings are lubricated using either grease nipples or grease pots, depending on the specification of the windlass, using a marine grease such as Castrol Spheerol SX2. The input shaft bearings should be either greased or oiled using gear oil, depending on whether the windlass is fitted with grease nipples or oil galleries. Castrol Shpeerol LCX 6002 Should be applied the gears in a thick coating, making sure that all surfaces are thoroughly covered. Technical data sheets for both of the greases mentioned above, can be downloaded from the downloads area on this page. Finally, the third aspect of maintenance is protection. The windlass should be covered when the vessel is not in use or if the windlass is not in use for any extended periods of time.

Downloads

Grease Spheerol LCX 6002