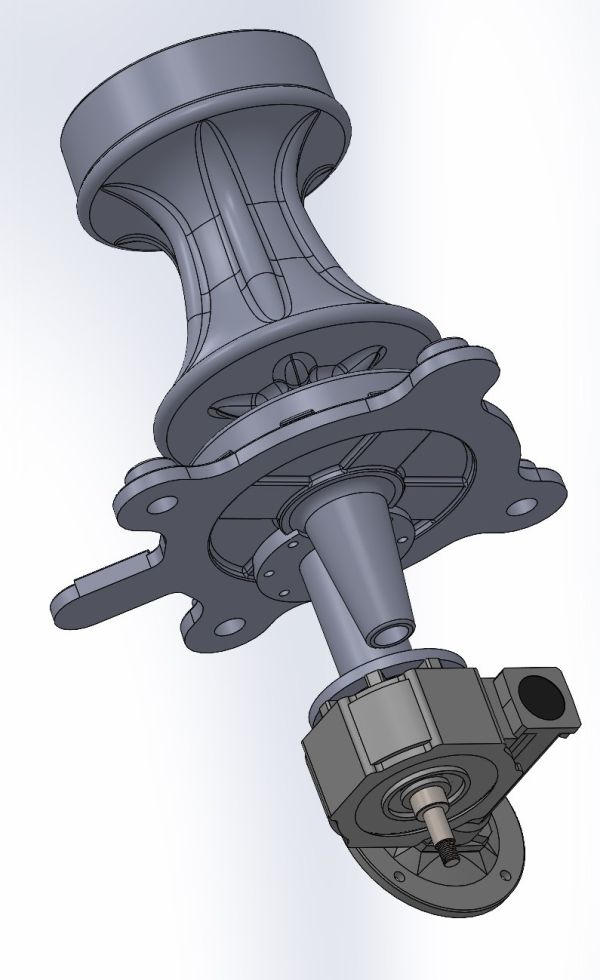

Tally Ho's old capstan, with a powered drive arrangement in development.

Using scans of the original components, we have added parts, consisting of an internal ring gear underneath the base of the main capstan housing, with a drive shaft running up through the base plate to engage with the ring gear. The electric motor and reduction gearbox is below deck and an electronic motor controller is used to manage the operating characteristics of the 48V motor. The level of control can be seen when the capstan is being operated in this video (link below). Specifically at 23:05 into the video, and with no load, the motor controller allows Leo to inch the chain and anchor into the stowed position.

This link will take you to the video showing the final installation of the capstan onboard Tally Ho