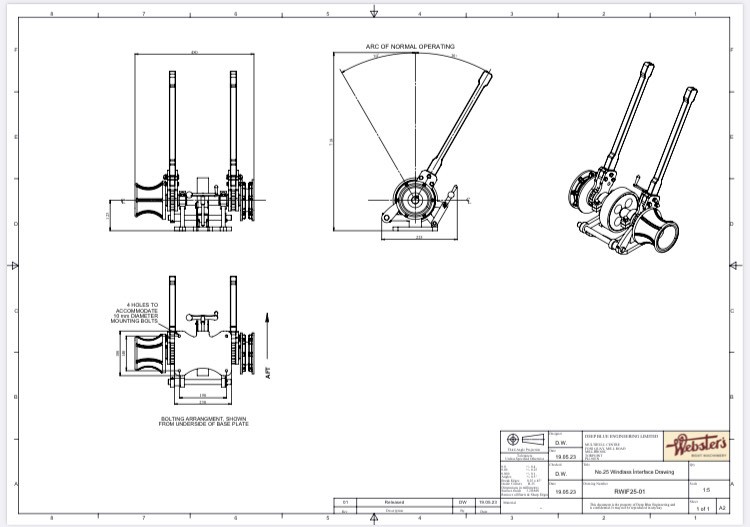

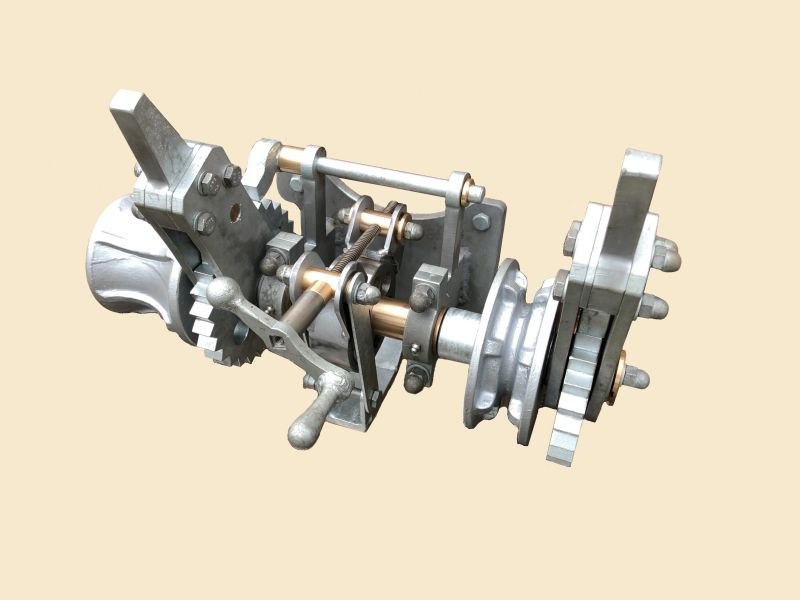

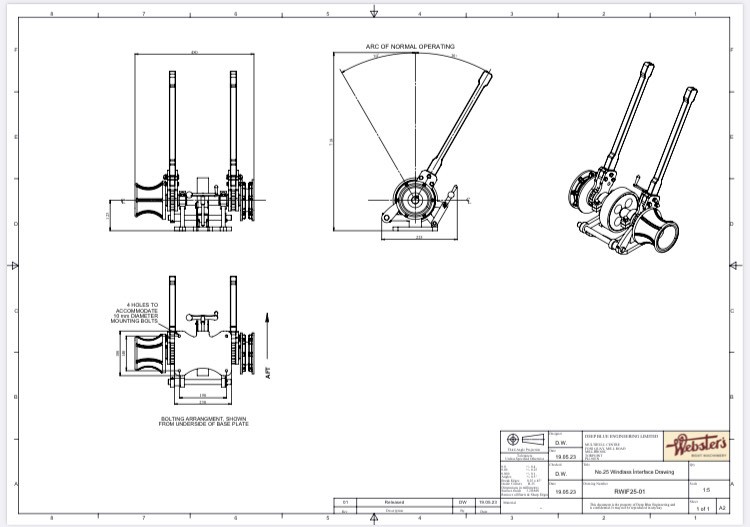

The No.30 windlass is a manually operated ratchet and lever based windlass. It is effectively double-acting, as a result of alternate fore and afte movements of each handle by the operator, which achieves constant rotation of the gypsy and warping drum. They can be either deck or bits mounted; the images here showing a bits mounted No.30.

For more information on this model windlass, please click on Additional Information below.

- Additional Information L30 Manual Ratchet Windlass

-

The No.30 is a mid-sized windlass, designed for vessels of up to around 25 tonnes displacement. It can be supplied with foot or hand operated brake arrangements, although this depends on the installation; clearly foot operated brakes are not recommended for bits mounted windlasses. The hand operated brake can either be fitted with a galvanised 'T' handle as in the images on this page, or a cast bronze Webster's hand wheel as seen on some of the other windlasses in the range. Gypsies for chain sizes 10, 12 and 13 mm can be supplied with this windlass, although specials can be machined in house for any desired size of chain within this range. The cast warping drum has five whelps which help prevent slippage of the rope when in use. This makes the process of using the warping drum as a remotely operated brake during anchor deployment more reliable. MAINTENANCE The main shaft bearings are lubricated via grease nipples installed into the bearing caps; the pawl is also fitted with a grease nipple. The brake assembly can be greased using a pot of grease and a brush such as a small paint brush. A light oil is recommended for the pawls inside of the ratchet assemblies, and then the same grease pot and brush method for applying grease to the ratchet/star wheel part of the ratchet assembly. The windlass should be covered when the vessel is not in use or if the windlass is not in use for any extended periods of time.

- SAFETY

-

With deck machinery generally there is a need to take great care and maintain a high level of awareness with regard to the moving parts of both the machinery and associated equipment such as ground tackle, chain, ropes etc. Operating and Maintenance details can be downloaded from this site, and should be read and understood before attempting to operate the windlass. The procedures for anchor deployment and retrieval provide warnings, aimed at alerting the operator to potential hazards and therefore it is essential that the procedures are followed carefully.

- MAINTENANCE

-

The main shaft bearings are lubricated via grease nipples installed into the bearing caps; the pawl is also fitted with a grease nipple. The brake assembly can be greased using a pot of grease and a brush such as a small paint brush. A light oil is recommended for the pawls inside of the ratchet assemblies, and then the same grease pot and brush method for applying grease to the ratchet/star wheel part of the ratchet assembly. The windlass should be covered when the vessel is not in use or if the windlass is not in use for any extended periods of time.

Downloads

Ratchet Windlass O&M Manual