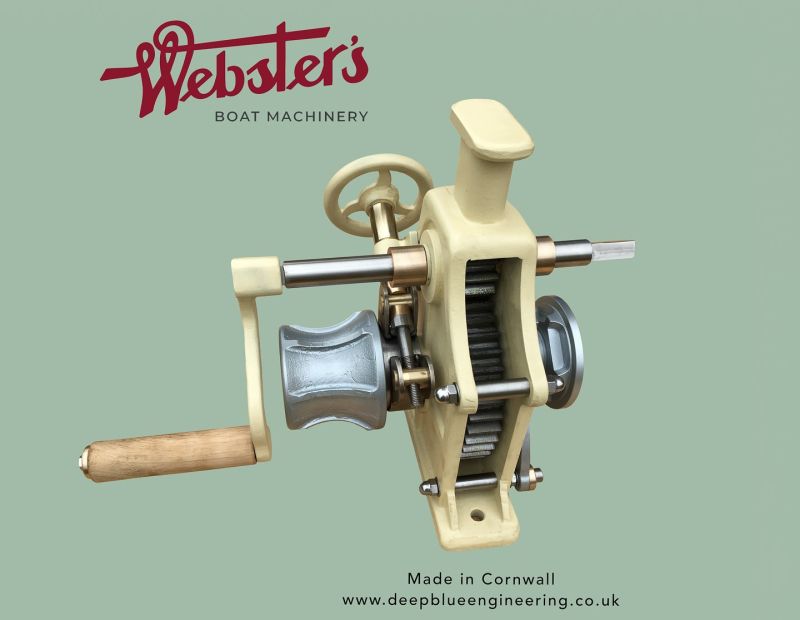

The most popular of the geared windlasses; this No.1N model, is a handsome and practical windlass, for vessels up to around 17 tonnes displacement. Accessories are available, which can help boost the capability of the windlass when short handed. For more details on this windlass, click on the Additional Information link below.

- No.1N Windlass Additional Information

-

This windlass can be supplied with a chain gypsy to accommodate 8, 10 and 12 mm chain, plus special sizes within the same range, for example imperial chain sizes, can be machined in-house if necessary. The specification can vary based on the materials used and the functionality. For example an all bronze version can be supplied, but the more common specification tends to be with a painted iron housing, and either bronze or iron chain gypsy and warping drum. The base model, which we refer to as the 'work boat' specification, has a painted iron housing, painted iron chain gypsy and warping drum, with other parts mainly in galvanised steel. Some components however are always made in bronze, as part of the mechanical design, for example bearings, brake nuts and some washers and spacers. The brake can be supplied as foot operated or hand operated, with either a galvanised 'T' handle, or a bronze Webster's hand wheel as seen on the examples shown above. An additional crank handle can be supplied, so that two members of crew can operate the windlass, which can help when there is a heavy load to lift, such as removing a well set anchor from a muddy anchorage. However, a ratchet handle can also be used during a heavy lift, by a single operator when short handed or solo sailing. Both accessories are linked below. to MAINTENANCE The main bearings are greased via grease nipples positioned on the windlass housing, close to the main shaft bearings, or grease nipples installed into the ends of the main shaft. The input shaft bearings in most cases are greased via grease nipples installed into the housing near to the input shaft bearing. Using a grease pot and paint brush, grease can be applied to the brake assembly, main gear and input pinion gear. The pawl may be fitted with a grease nipple, depending on the specification of the windlass, but if not, the pawl can be lubricated with a light gear oil followed by the application of grease in order to retain some of the light oil within the pawl shaft/pawl bearing area. The windlass should be covered when the vessel is not in use, or when the windlass is not in use for extended periods of time.

- SAFETY

-

With deck machinery generally there is a need to take great care and maintain a high level of awareness with regard to the moving parts of both the machinery and associated equipment such as ground tackle, chain, ropes etc. Operating and Maintenance details can be downloaded from this site, and should be read and understood before attempting to operate the windlass. The procedures for anchor deployment and retrieval provide warnings, aimed at alerting the operator to potential hazards and therefore it is essential that the procedures are followed carefully.

- MAINTENANCE

-

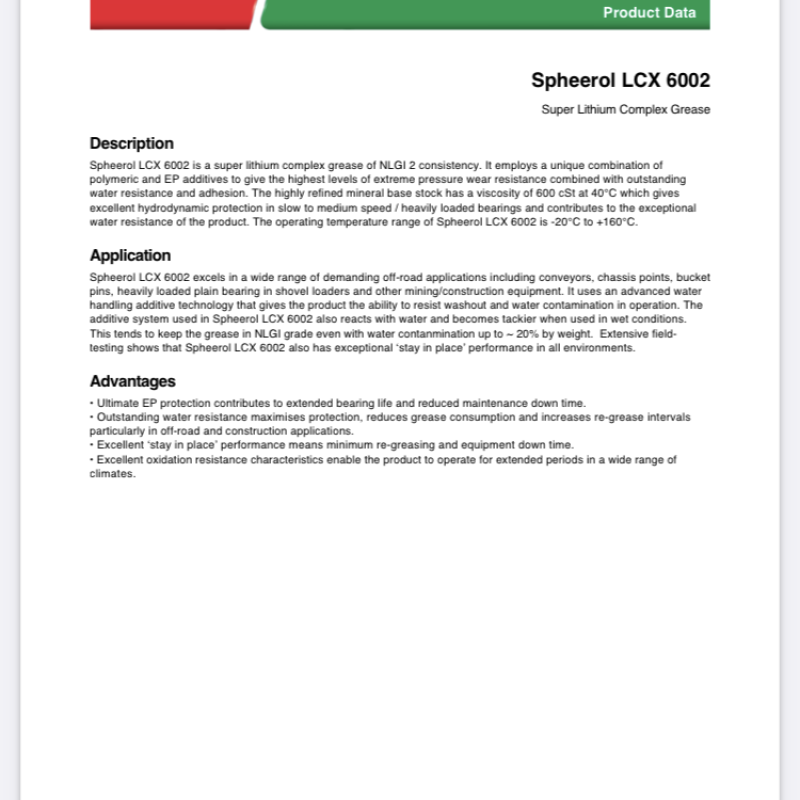

There are three main aspects to the maintenance of these windlasses. The first is a periodic, basic visual check, to establish there are no loose fastenings or any other anomalies which require attention. The frequency of this inspection will depend on how often the windlass is used, and will be at the discretion of the owner/skipper. Sail training and charter businesses use these windlasses, and it is common for the anchor to be used, sometimes several times in one day. Under these circumstances is is beneficial to make checks frequently, perhaps weekly, through the season. On most privately owned leisure vessels however, the inspection frequency could be monthly through the season, but clearly it is good practice to keep a vigilant eye on systems and machinery at all times. The second aspect is lubrication. The main shaft bearings are lubricated using either grease nipples or grease pots, depending on the specification of the windlass, using a marine grease such as Castrol Spheerol SX2. The input shaft bearings should be either greased or oiled using gear oil, depending on whether the windlass is fitted with grease nipples or oil galleries. Castrol Shpeerol LCX 6002 Should be applied the gears in a thick coating, making sure that all surfaces are thoroughly covered. Technical data sheets for both of the greases mentioned above, can be downloaded from the downloads area on this page. Finally, the third aspect of maintenance is protection. The windlass should be covered when the vessel is not in use or if the windlass is not in use for any extended periods of time.

Downloads

Number One O&M Manual

Grease Spheerol LCX 6002

Grease Spheerol SX2